Choosing the Right Material for Pipes and Round Bars

When it comes to selecting the right materials for pipes and round bars, it is essential to understand the various properties of each material to ensure durability, performance, and cost-effectiveness in your application. Different materials exhibit unique characteristics, making them suitable for specific uses across industries like manufacturing, automotive, aerospace, and construction.

This blog provides a detailed comparison of the most common materials used for pipes and round bars, including key properties like tensile strength, yield strength, hardness, corrosion resistance, temperature resistance, and cost. Whether you need heavy-duty pipes or general-purpose round bars, understanding these materials will help you make the best choice.

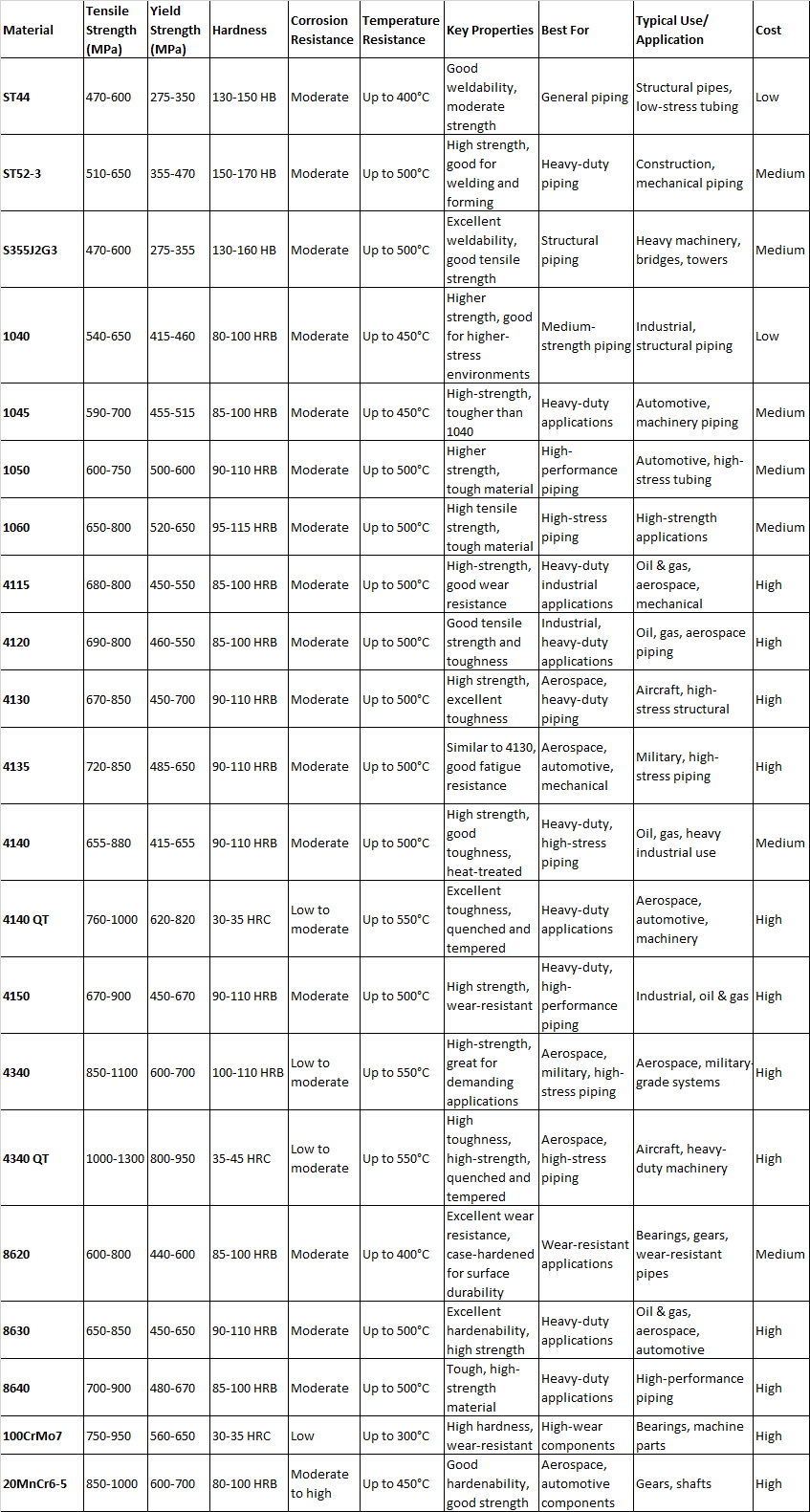

Material Comparison for Pipes

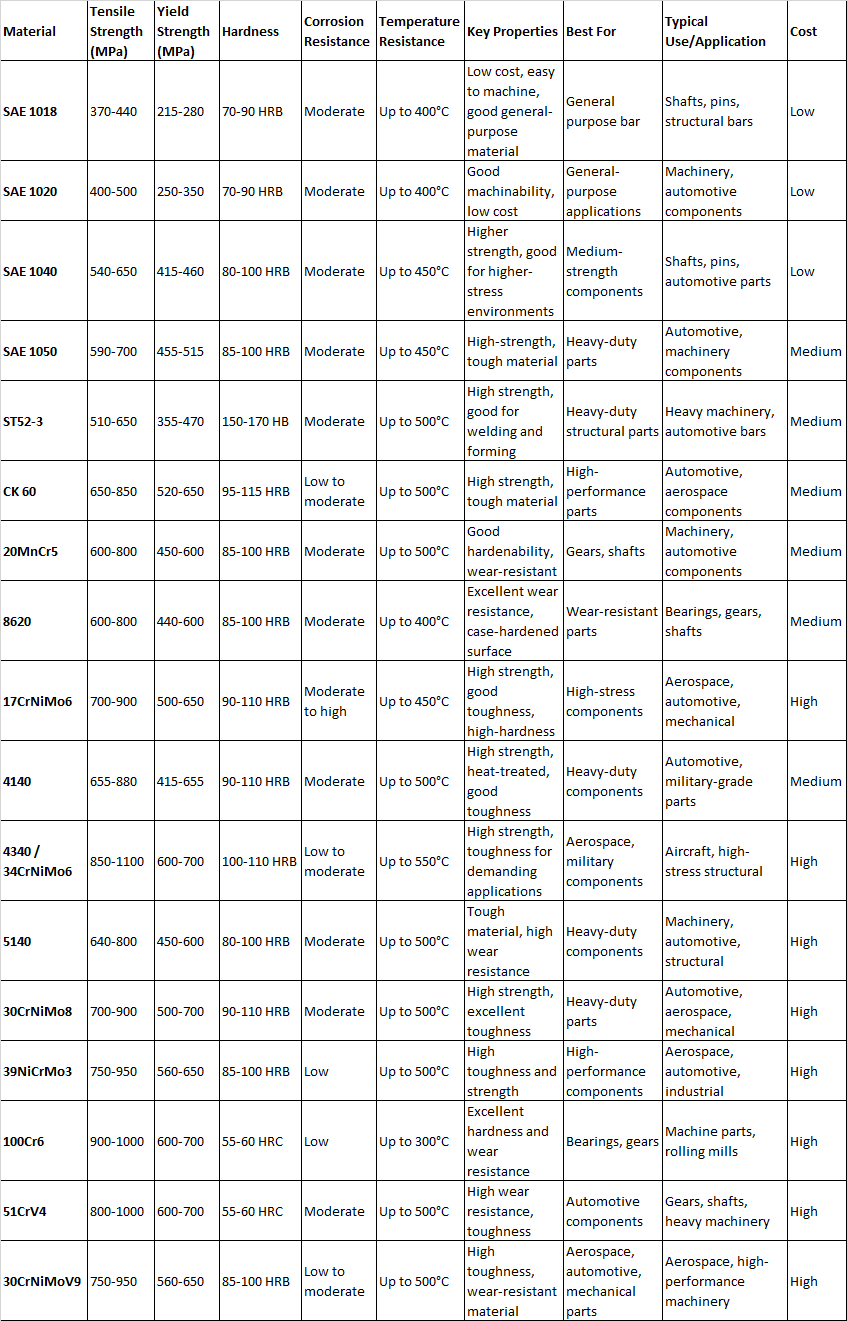

Material Comparison for Round Bars

Key Insights for Material Selection

Best Overall Performance:

SAE 4340 Alloy Steel offers the best combination of high tensile strength (up to 1100 MPa) and yield strength (up to 700 MPa), making it the ideal choice for heavy-duty applications. This material is particularly suited for aerospace, military-grade components, and high-stress industrial machinery. Its moderate corrosion resistance and temperature resistance up to 550°C provide exceptional durability in extreme conditions, ensuring long-lasting performance in demanding environments.

Best for Wear Resistance:

SAE 100Cr6 Roller Steel is specifically engineered for high wear resistance, making it an excellent choice for bearings, machine parts, and applications where components experience continuous friction. With a hardness of 55-60 HRC, it excels in environments where parts are subject to frequent wear and tear. While its corrosion resistance is low, this material performs optimally in controlled environments, where wear resistance is the priority.

Best for Cost-Efficiency:

SAE 1018 Carbon Steel is an excellent choice for applications that prioritize affordability without compromising good machinability. While it has moderate tensile strength and yield strength, it provides great cost efficiency for general-purpose piping and low-stress parts. This material is highly versatile and ideal for use in a variety of industries where performance requirements are more balanced and where cost is a primary concern.

Best for Heat Resistance:

SAE 4140 Alloy Steel and SAE 4340 Alloy Steel are both excellent choices for high-stress applications in elevated temperatures. With temperature resistance up to 500°C for SAE 4140 and up to 550°C for SAE 4340, these materials are ideal for industrial, military, and aerospace applications where both strength and heat resistance are critical. Their ability to maintain their mechanical properties at high temperatures makes them reliable choices for engine components, turbine blades, and other demanding environments.

Why Consider Exclusive Steels?

1. High Performance in Extreme Environments:

Materials such as SAE 30CrNiMo8 and SAE 100Cr6 are engineered to withstand extreme operational conditions. SAE 30CrNiMo8 (a high-alloy steel) is designed for heavy-duty applications where parts undergo constant high-stress conditions, such as gears and crankshafts. SAE 100Cr6, a high-carbon steel, is optimized for applications requiring superior wear resistance, such as bearings and machine components exposed to continuous friction.

2. Fatigue and Wear Resistance:

Exclusive steels like 50CrMoV4 and 50CrV4 offer exceptional fatigue resistance and wear resistance, making them suitable for high-load and high-stress components in automotive, aerospace, and industrial machinery applications. Their strength and toughness help extend the lifespan of critical parts subjected to constant wear.

3. Corrosion Resistance:

Certain exclusive steels are specifically designed for corrosive environments. For example, X19CrNiMo4 and X20Cr13 are stainless alloys known for their high corrosion resistance and ability to perform in severe environmental conditions, such as in chemical processing, oil and gas industries, and marine applications. These steels offer enhanced protection against corrosion while maintaining mechanical strength.

4. Tailored Mechanical Properties for Demanding Applications:

Exclusive steels are often tailored for specific needs where standard materials fall short. SAE 52100 and SAE 3415/14NiCr18 are examples of premium steels used for specialized components in high-performance applications, such as cutting tools, dies, and high-load mechanical parts that require precise tensile strength and hardness.

5. Superior High-Temperature and High-Pressure Resistance:

Special alloys like SAE 30CrNiMoV9 and 36CrNiMo16 are designed to excel in high-temperature applications and environments with high pressure. These steels are used in power generation and aerospace, where components are exposed to extreme heat and stress over prolonged periods, yet they maintain structural integrity and performance.

6. Cost vs. Long-Term Value:

While exclusive steels often come with a higher initial cost, their extended service life, reduced maintenance needs, and resilience in challenging environments make them a valuable long-term investment. 50CrMoV4 QT+PEELED, for instance, provides superior performance in high-load mechanical components, reducing the need for frequent replacements or repairs, which can offset the initial expense.

In conclusion, exclusive steels like SAE 30CrNiMo8, SAE 100Cr6, and others provide tailored properties that make them indispensable in industries where performance under stress, durability, and resistance to harsh conditions are essential. These materials are ideal for applications ranging from aerospace and automotive to heavy industrial machinery. Choosing these alloys ensures reliability, extended lifespan, and reduced operational costs over time.

Conclusion

Choosing the right material for your pipes and round bars is crucial for ensuring long-term performance and cost-effectiveness. By understanding the properties of materials like SAE 1018 Carbon Steel, SAE 1040, SAE 4140, SAE 4340, and SAE 100Cr6, you can select the best option based on factors like strength, durability, cost, and specific applications. Whether you need materials for low-stress applications or high-performance systems, this guide will help you make an informed decision that aligns with your needs.

When making your selection, consider the operating conditions of your application, including temperature, stress levels, corrosion exposure, and wear resistance to choose the material that will provide the best combination of strength and durability at the lowest cost.